For fully filled pipes

Ductus

Product categories

Stationary Time-Of-Flight flowmeter

Water

Hydropower,

Irrigation,

Hydrology

Wastewater

Ultrasonic

System technology

Wired

Modbus,

Ethernet,

other

Wireless

LTE-4G,

other

Instruments

Smart Infrastructure

Smart City

Smart Industry

Your benefits

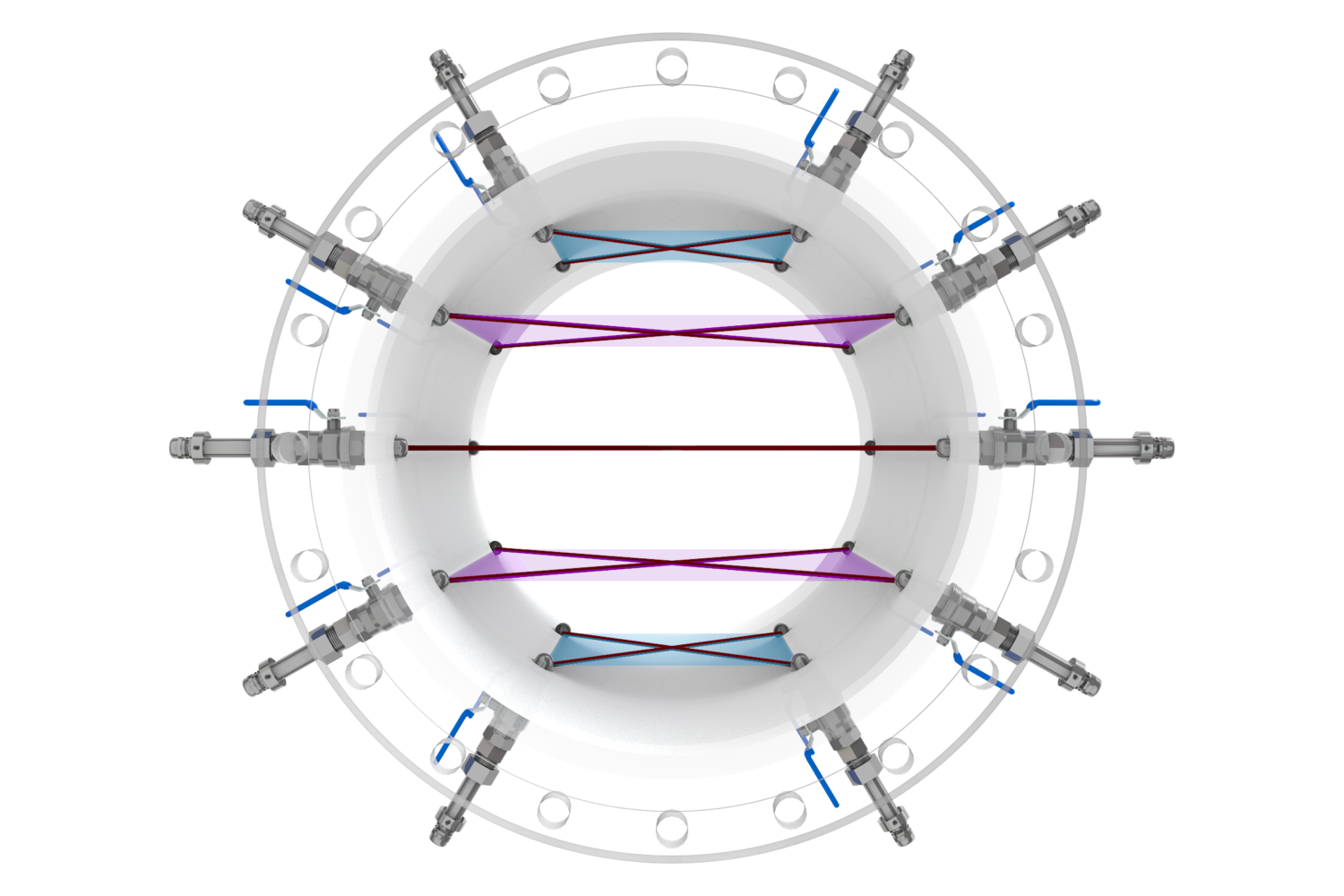

- Up to 10 acoustic measurement paths:

Exceptional accuracy, repeatability and linearity over the entire measurement range - Complete installation flexibility:

Reliable results independent of installation conditions. No straight runs necessary even with 90° elbows, valves, or pumps (swirl) - Patented velocity profile correction:

No need for flow straighteners or timeconsuming on-site calibration - Measurement of lowest flows:

Exact balancing, fast detection of network losses and in-depth understanding of operational processes - Clamp-on option available:

Easy and non-intrusive mounting without process interruption guarantees minimal installation costs

Applications

- Pressurized pipes 100 – 10‘000 mm in diameter

- Suitable for sites with difficult installation settings, e.g. pumps, valves or 90° elbows

- Ideal for applications with non-uniform (swirl), rapidly changing or close to zero flow conditions

- Permanent flow monitoring for applications in:

- Water distribution networks

- Reservoir monitoring

- Hydropower plants

- Wastewater and industry

Options

- Feedthrough sensors if pipe can be dewatered for installation

- Internal mount sensors if pipe is only accessible from the inside

- Clamp-on sensors for non-intrusive flow measurement

- 1 to 10 acoustic measurement paths

Properties

- Compact aluminium housing, IP66

- Wetted sensors: Feedthrough or from the inside of the pipe

- Enables measurement of turbine and pump efficiency compliant with IEC 60041 and ASME PTC 18

- Dry sensors: Clamp-on for easy installation, compliant with ISO12242

- Time of flight technology with digital signal processing

- Multiple analog and digital outputs, user programmable

- Integrated Wi-Fi access point

- Measurement in multiple planes with single or crossed paths

- U0/D0, no need for flow conditioners or on-site calibration

- Bi-directional measurement over the entire flow range

- Uncertainty down to ± 0.15 % of measured flow value

- Zero stability <1 mm/s, Repeatability <± 0.02 %

- Measurement of low velocities down to 1,5 mm/s

- Internal data storage 16 GB

- Graphical user interface in multiple languages

- All units for display and data storage can be customized by the user

- Communication: Ethernet, Modbus RTU/TCP, optional 4G/3G/2G modem

- Power supply: 100-240 V AC or 9-36 V DC

Product information

Product description

Ductus is a time of flight system designed for highly accurate flow measurement in water distribution networks and hydropower plants.

Flow monitoring is very often mandatory in the area of water supply and industry. Quite frequently, the pipe systems are complex and contain valves and pumps. Due to the patented velocity profile compensation of GWF's Ductus, no flow straighteners or on-site calibration are required. The unique digital signal processing allows the detection of even the smallest time differences, i.e. even the smallest amounts are determined accurately.

WebUI (Wi-Fi)

Ductus is equipped with an integrated web server running a WebUI. You can display and manage the WebUI using the standard web browser of your smartphone, tablet, PC or notebook. There is no need for any additional software or App. Parameter setting and data visualization has never been so easy.

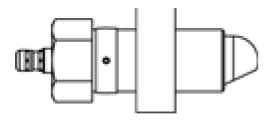

Transducer replacement

In the unlikely event that a transducer should fail, Ductus can be programmed to automatically compensate for the loss in path information with little reduced accuracy. Additionally, the operator is advised that an alarm is present.

The feedthrough transducer housings are separated from the transducers themselves and are designed to allow removal of the entire sensor for repair, replacement, or cleaning without the need to dewater the pipe or shut down the process.

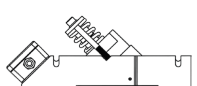

Ductus installed after a 90° elbow

Measuring principle

Space constraints and application configurations lead to complex flows in pipes which contain elbows, tees or other disturbing and non-uniform elements. This leads to difficulties in installing flowmeters at an optimum location; which is defined by a minimum distance upstream or downstream of known disturbances at which a fully developed velocity profile is present. For traditional flowmeters, significant errors may be caused by these adverse installation conditions.

In contrast to conventional systems, Ductus provides detailed information on the flow velocity profile. An accurate measurement of the flow rate can be achieved by replicating the flow velocity profile across the pipe. Accuracy is maximized using predetermined conduit configuration parameters and correction factors, which incorporate the specific local installation conditions.

Conventional flowmeters are also sensitive to velocity profiles with a large rotational component (swirl). Swirl can be caused by pumps or multiple out-of-plane changes in flow direction. It is present to some extent in almost every application and can generate significant transverse velocity components; and it takes a long distance to dissipate. If the swirl is not accounted for, it can cause significant errors. Ductus can quantify and correct these disrupting factors without difficulty. The Ductus system keeps its measurement accuracy even when asymmetric profiles and swirls are present in the flow.

Wetted sensors arranged in five parallel planes

Component description

The Ductus system is composed of a wall-mounted transmitter and several sensor options. For non-intrusive measurement, clamp-on transducers are available. If the pipe can be dewatered for installation, feedthrough or internally mounted sensors are suitable options. For multi-path systems, a separate housing to connect up to 20 transducers is available.

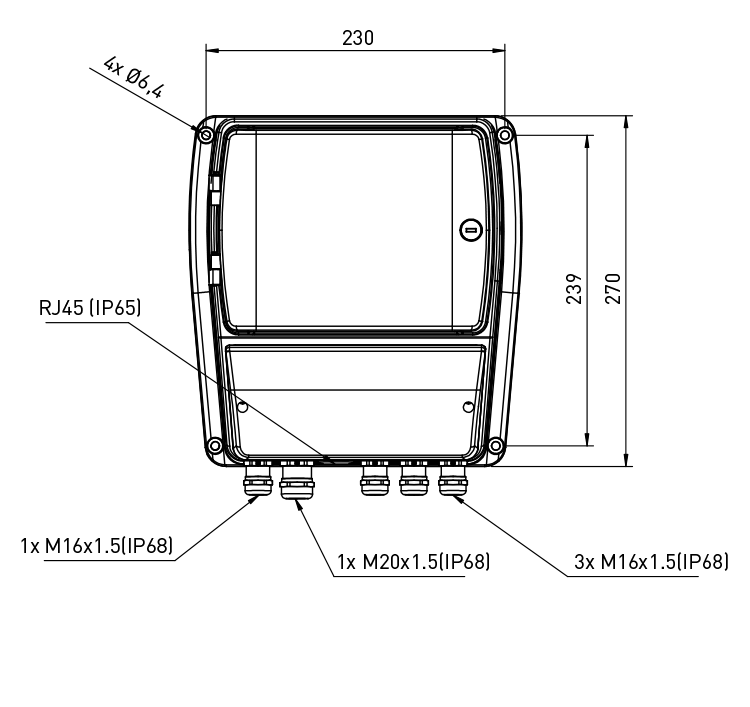

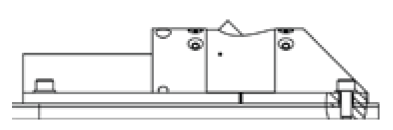

Standard transmitter and Multi-path extension housing

Transmitter

The Ductus transmitter incorporates all the required algorithms and software to ensure measurement accuracy and repeatability. The IP66 (NEMA 4X) compact housing features a 4 x 20 alphanumeric LCD display and a 4 button keypad.

All configuration data as well as measured and calculated data are stored inside a 16 GB MicroSD card. The transmitter controls the measurements, calculates the flow rate and provides freely programmable current outputs, status alarms, frequency outputs and totalizer readings.

The Ductus standard transmitter accommodates 2 acoustic paths. For systems with up to 10 measurement paths, an extension housing is available

CO-L, clamp-on sensor 200 kHz and CO-S, clamp-on sensor 1 MHz

Clamp-on transducers

When combining the Ductus with clamp-on transducers, the flow measurement becomes non-intrusive. The transducers are installed with little technical effort and without process interruption on the pipeline. This non-invasive measurement method is suitable for various media such as wastewater, salt water and glycol.

Clamp-on transducers require no modification of the conduit or plant shutdown. Once the CO-L sensors have been installed, they can easily be removed from the mounting system, for example to renew the coupling paste. This prevents a shift of the installation position.

FT-S and FT-L feedthrough sensors and Internal mount sensor TD-IM

Wetted sensors

Depending on your individual requirements, several options of feedthrough sensors are available. For the sensor type FT-S the pipe only needs to be dewatered for the initial installation. Removal of these sensors for cleaning, repair or replacement is possible without process interruption.

If the pipe is accessible only from the inside, internally mounted sensors are a suitable option.

Technical data

Transmitter

| Ductus | |

|---|---|

| Range | 0 bis ± 20 m/s |

| Repeatability | <± 0.02 % |

| Zero stability | <1 mm/s |

| Data logger | 16 GB MicroSD card |

| Communication | RS-485 or RS-232, Modbus RTU/TCP, Wireless LAN, 4G (LTE) / 3G (HSPA+) / 2G, Ethernet 10/100 Mbps |

| Inputs | max. 4 x 4-20 mA, 2 x digital |

| Outputs | max. 4 x 4-20 mA, 4 x relay, 2x digital |

| Power supply | 9-36 V DC or 100-240 V AC (50/60 Hz) |

| Enclosure | Aluminium |

| Ingress protection | IP66 (NEMA 4) |

| Ambient temperature | -15 °C bis +60 °C |

| Storage temperature | -20 °C bis +70 °C |

| Dimensions | 270 mm x 256 mm x 139 mm (L x B x H) |

| Ductus multi-path extension | |

|---|---|

| Acoustic paths | 3 to 10 |

| Power supply | 9-36 V DC |

| Enclosure | Aluminium |

| Ingress protection | IP66 (NEMA 4) |

| Ambient temperature | -15 °C bis +60 °C |

| Storage temperature | -20 °C bis +70 °C |

| Dimensions | 301 x 270 x 118 mm (L x B x H) |

Wetted Sensors

|

FT-S FT-S |

FT-L1000 FT-L1000 |

TD-IM TD-IM |

|---|---|---|---|

| Frequency | 1 MHz | 1 MHz | 200 kHz |

| Beam width | 5° (-3 dB) | 10° (-3 dB) | 18° (-3 dB) |

| Pipe diameter | 0,1 m bis 2 m | 0,3 m bis 5 m | 1,0 m bis 10 m |

| Uncertainty velocity | up to ± 0.15 % of reading (10 paths) | up to ± 0.15 % of reading (10 paths) | up to ± 0.15 % of reading (10 paths) |

| Pressure rate | 20 bar (other on request) | 20 or 40 bar | 60 bar |

| Material | stainless steel | stainless steel | stainless steel / polyamide |

| Process temperature | 0 °C bis +40 °C | 0 °C bis +40 °C | 0 °C bis +40 °C |

| Storage temperature | -20 °C bis +70 °C | -20 °C bis +70 °C | -20 °C bis +70 °C |

| Dimensions | Ø 1", Länge: 293 mm | Ø 1 1/2", Länge: 186 mm | 320 x 100 x 70 mm (L x B x H) |

| Installation | ball valve and welding socket | welding socket or thread | from the inside |

Clamp-on transducers

|

CO-L CO-L |

CO-S CO-S |

|---|---|---|

| Pipe diameter | 0,4 m to 15 m | 0,05 m to 1 m |

| Pipe wall thickness | up to 100 mm (steel, plastic, glass fiber | up to 25 mm |

| Uncertainty velocity | up to ± 0.5 % of reading | up to ± 0.5 % of reading |

| Frequency, Beam width | 200 kHz, 8° (-3 dB) | 1 MHz, 5° |

| Material | stainless steel, POM | stainless steel |

| Process temperature | 0 °C to +40 °C | 0 °C to +40 °C |

| Ambient temperature | -20 °C to +60 °C | -20 °C to +60 °C |

| Storage temperature | -20 °C to +70 °C | -20 °C to +70 °C |

| Dimensions | 270 x 115 x 100 mm (L x W x H) | 56 x 32 x 25 mm (L x W x H) |