Multijet domestic water meter

MTKcoder® MP

Product categories

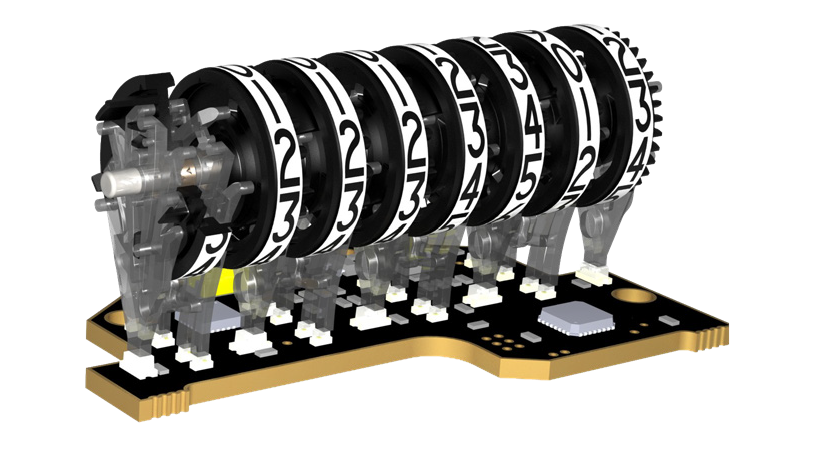

The proven GWFcoder® system reads the absolute, mechanical totalizer reading precisely and reliably and makes the data available via standardized interfaces. The number rolls with three asymmetrically arranged slots of different lengths are scanned via five light guides equipped with light-emitting diodes (LEDs).

Water

Drinking Water

Mechanical

Wired

M-Bus

Smart City

Smart Building

Your benefits

- Mechanical roller register with 1-litre-resolution:

Efficient consumption monitoring in smart metering applications - Revolutionary Multiprotocol interface:

Investment security due to the interoperability of the meter - Transfer of the effective meter reading:

No data loss and guaranteed security of the billing data - Batteryless register:

No service life restriction - No programming required when commissioning the meter in a readout system (Plug & Play):

Easy and fast on-site installation - Standardised interface:

No service life restriction - Long service life, robust domestic water meter:

Excellent measuring stability and reliability - Measurement of low flow rates:

Increased cost effectiveness

Applications

- Automated mobile or fixed network readout of relevant billing data

- Wired or radio remote readout of hard to access metering installations, e.g. meter pits, reservoirs

Options

- Flood proof MTKcoder® MP register (IP68) with Multiprotocol interface and meter lid / 5 m cable

- Radio module RCM®-H200 compact or RCM®-H200 split

Dokumentation: RCM®-H200 - EPe40265

Dokumentation: RCM®-H200 - EPe40265 - Radio module RCM®-LRW...

Dokumentation: RCM®-LRW... - EPe40261

Dokumentation: RCM®-LRW... - EPe40261

Properties

- Multijet impeller wheel, super dry-dial, magnetic coupling

- Q3 4–25: Measuring range R160

- 8 dial resolution with 3 comma place

- Maximum operation pressure PN 16 bar

- Maximum operating temperature 50 °C

- Horizontal or vertical installation (Vertical riser/down pipe)

- High grade wear resistant and corrosion proof materials

- Inlet strainer

- Reconditionable and recyclable execution

- Materials suited for contact with potable water

Conformity according to European Measuring Instruments (MID)

Conformity according to European Measuring Instruments (MID)- Standard register with Multiprotocol interface

- M-Bus standard unit load: 2 unit loads (3 mA)

Product information

Technical Data

| Execution | MTKcoder® MP (horizontal) | MTKcoder® MP-VS oder -VF (vertikal)1) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Nominal diameter | DN | mm | 20 | 25 | 32 | 40 | 50 | 20 | 25 | 32 | 40 |

| Connection thread on meter | G...B | Zoll | 1 | 1¼ | 1½ | 2 | 2⅜ | 1 | 1¼ | 1½ | 2 |

| Connection thread on coupling | R... | Zoll | ¾ 2) | 1 | 1¼ | 1½ | 2 | ¾ 2) | 1 | 1¼ | 1½ |

| Operating pressure | PN | bar | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 |

| Nominal flow rate | Q3 | m3/h | 4 | 6.3 | 10 | 16 | 25 | 4 | 6.3 | 10 | 16 |

| Overload flow rate 3) | Q4 | m3/h | 5 | 7.875 | 12.5 | 20 | 31.25 | 5 | 7.875 | 12.5 | 20 |

| Transitional flow rate ±2% | Q2 | m3/h | 0.04 | 0.063 | 0.1 | 0.16 | 0.25 | 0.04 | 0.063 | 0.1 | 0.16 |

| Minimum flow rate ±5% | Q1 | m3 | 0.025 | 0.039 | 0.062 | 0.1 | 0.156 | 0.025 | 0.039 | 0.062 | 0.1 |

| Smallest readable volume | l | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 | |

| Maximum register reading | m3 | 100'000 | 100'000 | 100'000 | 100'000 | 100'000 | 100'000 | 100'000 | 100'000 | 100'000 | |

| Temperature | max °C | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | |

| Measuring range | R160 | R160 | R160 | R160 | R160 | R160 | R160 | R160 | R160 | ||

| Dimensions and weights | MTKcoder® MP (horizontal) | MTKcoder® MP-VS oder -VF (vertikal)1) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Length without couplings | A | mm | 220 | 260 | 260 | 300 | 300 | 105 | 150 | 150 | 200 |

| Length with couplings | mm | 310 | 370 | 370 | 434 | 454 | 195 | 260 | 260 | 334 | |

| Meter height with lid | B | mm | 125 | 135 | 135 | 160 | 174 | - | - | - | - |

| Meter height with inductive interface | B1 | mm | 137 | 147 | 147 | 172 | 186 | - | - | - | - |

| Meter height with radio module RCM®-H200 compact | B2 | mm | 162 | 172 | 172 | 197 | 211 | - | - | - | - |

| Meter height with lid from pipe centre line | C | mm | 85 | 91 | 91 | 114 | 117 | - | - | - | - |

| Meter height with inductive interface from pipe centre line | C1 | mm | 97 | 103 | 103 | 126 | 129 | - | - | - | - |

| Meter height with radio module RCM®-H200 compact from pipe centre line | C2 | mm | 122 | 128 | 128 | 151 | 154 | - | - | - | - |

| Meter depth with lid / inductive interface | D | mm | - | - | - | - | - | 148 | 169 | 183 | 226 |

| Meter depth with radio module RCM®-H200 compact | D1 | mm | - | - | - | - | - | 150 | 169 | 183 | 226 |

| Meter depth with lid / inductive interface from pipe centre line | E | mm | - | - | - | - | - | 130 | 143 | 156 | 190 |

| Meter depth with radio module RCM®-H200 compact from pipe centre line | E1 | mm | - | - | - | - | - | 132 | 143 | 156 | 190 |

| Installation depth with lid from pipe centre line | W | mm | 48 | 50 | 50 | 68 | 76 | 48 | 49 | 51 | 70 |

| Installation depth with radio module RCM®-H200 compact from pipe centre line 4) | W1 | mm | 64 | 64 | 64 | 68 | 76 | 64 | 64 | 64 | 70 |

| Installation depth IP68 or with inductive interface from pipe centre line 4) | W2 | mm | 57 | 57 | 57 | 68 | 76 | 57 | 57 | 57 | 70 |

| Meter height with open lid | G | mm | 173 | 183 | 183 | 208 | 222 | - | - | - | - |

| Weight without couplings | ca. kg | 2.1 | 2.6 | 2.7 | 5.4 | 6.7 | - | - | - | - | |

| Weight without couplings MTK-VS | ca. kg | - | - | - | - | - | 1.9 | 3.0 | 3.0 | 6.0 | |

| Weight without couplings MTK-VF | ca. kg | - | - | - | - | - | 2.0 | 3.4 | 3.7 | 7.3 | |

| Weight with couplings | ca. kg | 2.4 | 3.1 | 3.4 | 6.5 | 8.3 | - | - | - | - | |

| Weight with couplings MTK-VS | ca. kg | - | - | - | - | - | 2.2 | 3.5 | 3.7 | 7.1 | |

| Weight with couplings MTK-VF | ca. kg | - | - | - | - | - | 2.3 | 3.9 | 4.4 | 8.4 | |

1) -VS = Vertical riser / -VF = Vertical down pipe

2) Also supplied with couplings R½

3) Max. 1 h per 24 h, with max. total time of 100 h

4) By turning the register / assembly installation depth W can be realised 5) only in NPSM execution

| Certifications | MTKcoder® MP (horizontal) | MTKcoder® MP-VS oder -VF (vertikal)1) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| SVGW certification | x | x | x | x | x | x | x | x | x |

| UBA Brass (DIN 50930-6) | x | x | x | x | x | x | x | x | x |

| KTW / W270 | x | x | x | x | x | x | x | x | x |

| NSF-61-G & 372 | - | x 5) | - | x 5) | - | - | - | - | - |

5) only in NPSM execution

| Information | |

|---|---|

| EU-REACH Art. 33 / ChemV Art. 71 | Brass products contain lead > 0,1 % |

Measuring error curve

Typical Head Loss Curve

Materials

| Housing: | UBA Brass (DIN 50930-6) |

| Sealing plate: | UBA Brass (DIN 50930-6) |

| Impeller / measuring insert: | High grade synthetic materials |

| Bearings: | Hard metal, Sapphire, Chrome nickel steel |

| Seal material: | EPDM |

Dimension Diagram

Ausführungsvarianten

- ohne Kabel

- mit 1,5 m Kabel

- IP68 mit 5 m Kabel

Installation

| Pipeline: | horizontal | |

| vertical | ||

| Meter head: | upwards |

Installation Requirements

The meter must be installed so that the type plate is always horizontally positioned, facing upwards (do not tilt)

![]() Documentation: GWF water meters - BAdfei10207

Documentation: GWF water meters - BAdfei10207

GWFcoder®-Technologie

The 2nd generation – even more flexible

The well-established GWFcoder®-system reads the absolute mechanical register value precisely and reliably and provides the data through standardized interfaces. The number wheels with three various long, asymmetrically arranged slots are being scanned through light pipes which are connected to five light emitting diodes (LED). Thus, the exact position of each number wheel can be detected and the encoded absolute register read can be transmitted as part of the protocol by the GWFcoder®-interface. This GWF patented functional principle is being used in millions of installations worldwide since more than 15 years. The GWFcoder®-interface guarantees absolute correlation between the electronic readout and the register reading and provides an incomparably higher level of information compared to meters with pulse output. Meters with GWFcoder®-technology do not contain a battery which, in turn, does not compromise existing revision cycles. The readout device supplies the power for the readout.

GWF enhanced the reliable Smart Metering technology in its 2nd generation, so that 8 instead of 5 number wheels are being scanned and therefore a resolution of 1 liter is possible. Moreover, all products with multiprotocol functionality provide the flexibility to switch between SCR(IEC) and M-Bus which leads to an easy and fast «Plug & Play» installation on site.

In combination with the GWF radio module RCM®-H200 the third interface can be used for wireless M-Bus.

GWFcoder®-Data package

| SCR: IEC 62056-21 Mode A (IEC 1107) | |

|---|---|

| Medium: | Water |

| Absolute meter reading: | 12365,678 m3 |

| Serial number: | 13215678 |

| Meter size: | DN 20 |

| M-Bus | EN 13757 |

| ECO | EN 13757-3 |

Example of use

Wireless readout

Meter with GWFcoder® register is read out by radio using a mobile infrastructure.