Bulk water meters

Meistream with GWFcoder® MP

Categorías de productos

Large water meter with GWFcoder® totalizer MP for cold water up to 50 °C

Agua

Agua potable

Mecánico

Smart City

Sus ventajas

- Revolutionary Multiprotocol interface:

Investment security due to the interoperability of the meter - Transfer of the effective meter reading:

No data loss and guaranteed security of the billing data - No programming required when commissioning the meter in a readout system (Plug & Play):

Easy and fast on-site installation - Measurement of low flow rates:

Increased cost effectiveness - Removable measuring insert:

Retrofittability and replaceability guaranteed - One measuring insert for various bodies:

Lower storage costs

Aplicaciones

- Measurement of high flow rates, e.g.

- Downstream of pumps or at transfer points

- Reservoir inflows and outflows - Measurement of low flow rates during offpeak periods

- Automated mobile or fixed network readout of relevant billing data

- Wired or radio remote readout of hard to access metering installations, e.g. meter pits, reservoirs

Opciones

- High-pressure series up to PN 40 bar

- High-resolution pulse generator HRI

Documentation: HRI - EPe10213

Documentation: HRI - EPe10213 - Radio module RCM® split

Documentation: RCM® - EPe40232

Documentation: RCM® - EPe40232 - Radio module RCM®-LRW

Documentation: RCM®-LRW... - EPe40261

Documentation: RCM®-LRW... - EPe40261

Descargas

Características

- Universal installation position

- No straight flow section required before the meter

- Register can be turned through 355°

- Maximum operating pressure PN 16 bar

- Temperature up to 50 °C

- Rotor is hydrodynamically, radially, and axially balanced

- Available in the standard installation lengths for WS and WP meters

- Powder coating provides optimum corrosion protection

- Non-ferrous metal design up to PN 16 bar

- SVGW certification

Conformity according to the European Measuring Instrument Directive (MID)

Conformity according to the European Measuring Instrument Directive (MID)- Flood-proof register (IP68) with Multiprotocol interface (MP), 5 m cable and provision for a HRI pulser

- M-Bus standard unit load: 2 unit loads (3 mA)

Product information

Technical Data

| Nominal diameter 1) | DN | mm | 40 | 50 | 65 | 65 | 80 | 80 | 100 | 100 | 125 | 150 | 150 | 200 | 250 | 300 |

| Nominal pressure 2) | PN | bar | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 |

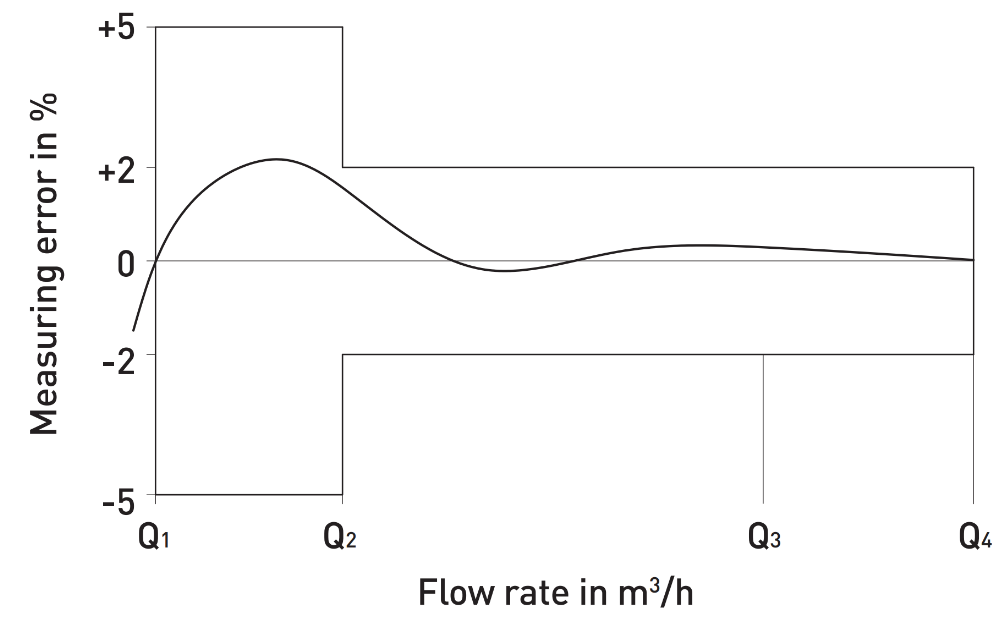

| Nominal flow rate | Q3 | m3/h | 50 | 50 | 70 | 70 | 120 | 120 | 230 | 230 | 250 | 450 | 450 | 800 | 1250 | 1400 |

| Overload flow rate (few minutes) | Q4 | m3/h | 90 | 90 | 120 | 120 | 200 | 200 | 300 | 300 | 350 | 600 | 600 | 1200 | 1600 | 2000 |

| Transitional flow rate ±2% | Q2 | m3/h | 0,4 | 0,4 | 0,63 | 0,63 | 0,51 | 0,51 | 0,81 | 0,81 | 1,02 | 1,6 | 1,6 | 4,03 | 6,3 | 16 |

| Minimum flow rate ±5% | Q1 | m3/h | 0,15 | 0,15 | 0,2 | 0,2 | 0,2 | 0,2 | 0,3 | 0,3 | 0,5 | 0,8 | 0,8 | 2 | 3,5 | 9 |

| Temperature | max.°C | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | |

| Dimensions and weights | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

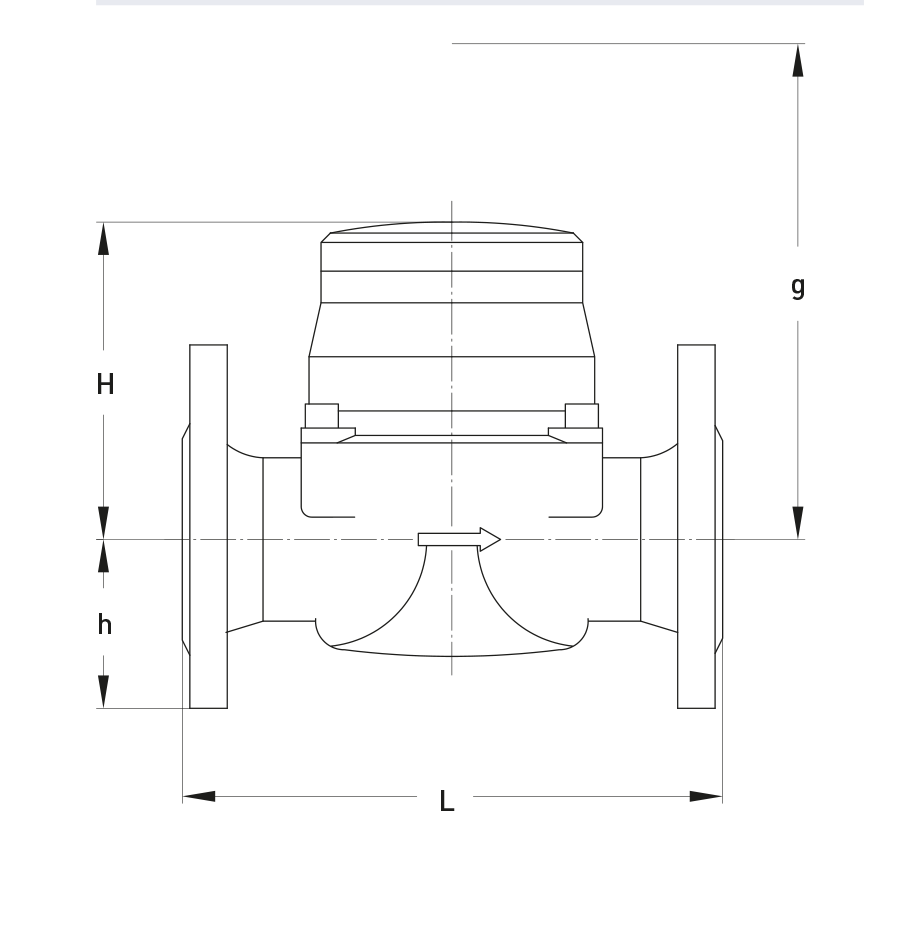

| Overall length | L | mm | 200 | 2703) | 200 | 300 | 2254) | 300 | 250 | 360 | 250 | 300 | 500 | 350 | 450 | 500 |

| Height | H | mm | 157 | 157 | 157 | 157 | 187 | 187 | 187 | 187 | 197 | 214 | 214 | 251 | 275 | 301 |

| Height | h | mm | 73 | 73 | 85 | 85 | 95 | 95 | 105 | 105 | 118 | 135 | 135 | 162 | 194 | 226 |

| Dismantling height of measuring unit | g | mm | 237 | 237 | 237 | 237 | 307 | 307 | 307 | 307 | 317 | 393 | 393 | 486 | 511 | 536 |

| Meter weight | app. kg | 7,8 | 9,6 | 10,1 | 12 | 14,2 | 16,3 | 18,2 | 20,2 | 20,7 | 35,9 | 35,9 | 56,9 | 79,4 | 103,8 | |

| Measuring unit weight | app. kg | 1,5 | 1,5 | 1,5 | 1,5 | 3,2 | 3,2 | 3,2 | 3,2 | 3,2 | 5,9 | 5,9 | 9,6 | 9,6 | 9,6 | |

| Body weight | app. kg | 6,3 | 8,1 | 8,6 | 10,5 | 11 | 13,1 | 15,0 | 17,0 | 17,5 | 30 | 30 | 47,3 | 69,8 | 94,2 | |

1) Nominal diameter DN 40 upon request

2) High-pressure series PN 40 upon request

3) Also available with 300 mm body length

4) Also available with 200 mm body length

| MID certification data | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nominal flow rate | Q3 | m3/h | 40 | 40 | 63 | 63 | 100 | 100 | 160 | 160 | 160 | 400 | 400 | 630 | 630 | 1000 |

| Temperature | max. °C | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | |

| Horizontal measuring range | R160 | R160 | R160 | R160 | R315 | R315 | R315 | R315 | R250 | R400 | R400 | R250 | R125 | R63 | ||

| Vertical measuring range | R100 | R100 | R100 | R100 | R125 | R125 | R160 | R160 | R125 | R200 | R200 | R250 | R100 | R63 | ||

| Standard marking | R100 | R100 | R100 | R100 | R100 | R100 | R100 | R100 | R100 | R100 | R100 | R100 | R100 | R63 | ||

Dimension Diagram

Materials

| Body | Cast iron |

| Measuring unit | Plastic |

| Rotor | Plastic |

| Other materials | Brass / non-rusting steel |

Measurement error curve

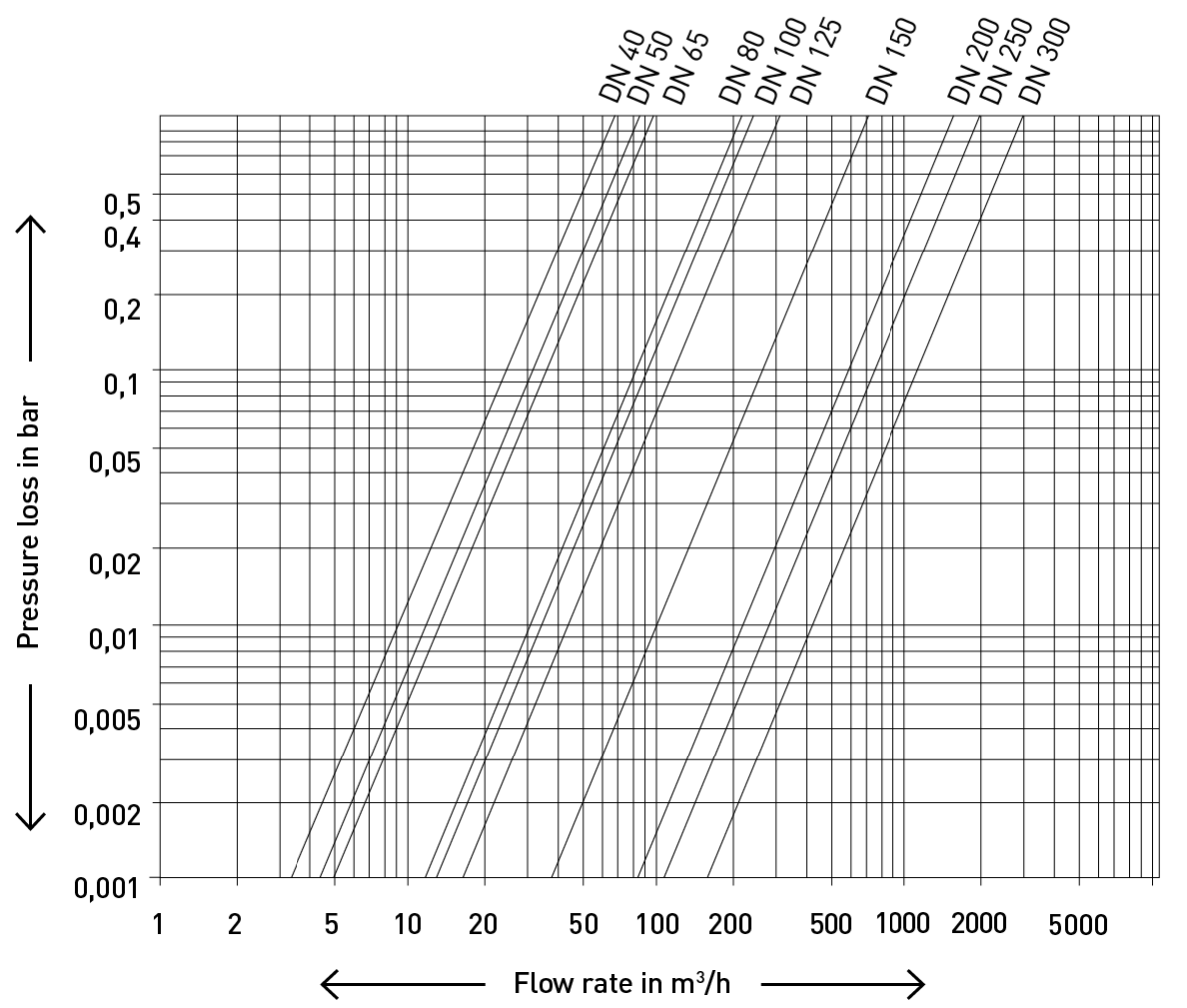

Typical Head Loss Curve

Installation

| Pipeline: | horizontal | |

| vertical | ||

| diagonal | ||

| Meter head: | upwards | |

| sideways |

Commission

When commissioning the meter the measureing section must be filled slowly (bleed slowly).

Dial

| Nominal size | DN | 50–125 | 150–300 |

| Smallest reading | m3 | 0,0005 | 0,005 |

| Maximum register reading | m3 | 1’000’000 | 10’000’000 |

Pulse values HRI Pulser

| Meter sizes | DN 50...125 1 Pulse = ...Liter | DN 150...300 1 Pulse = ...Liter |

|---|---|---|

| Meistream | 100 1000 | 1000 10000 |

GWFcoder®-Technology

In the GWFcoder®system, the individual rollers of the mechanical register are read out optoelectronically. The position of the various long asymmetrically arranged slits in the roller counters is scanned using 5 light barriers (lightpipe transmitter and receiver). The light barriers are implemented with phototransistors. LEDs, and light conductors, which are all consecutively scanned and evaluated. The precisely defined position of each individual roller counter is encoded as an absolute roller counter reading and read out as a part of the protocol via the GWFcoder® interface. This functioning principle is patented by GWF. The GWFcoder® interface, compared to a meter with a pulse output, has an incomparably higher level of information content and readout accuracy. A GWFcoder® register does not require a battery, which, in turn, does not compromise existing revision cycles. The readout device supplies the power for the readout.

Moreover, all products with multiprotocol functionality provide the flexibility to switch between wall readout (inductive or CL), Wired M-Bus or radio readout which leads to an easy and fast «Plug & Play» installation on site.

GWFcoder®-Data package

| Medium | Water |

| Absolute meter reading | 123654 m3 |

| Serial number | 43215678 |

| Meter size | DN 50 |

M-Bus: EN 13757 --> Cable colors black / red, polarity independent

ECO: EN 13757-3 --> Cable colors black / green / red, note polarity

Example of use

Wireless read-out

Meter with GWFcoder® register is read out automatically by radio using a mobile infrastructure (for example radio module RCM® and MEx).