Water measurement

sonico® EDGE

Product categories

Developed for highly precise flow measurement of drinking, industrial and service water.

Water

Hydrology,

Drinking Water

Wastewater

Ultrasonic

Wired

Impulse,

Modbus

Instruments

Smart Infrastructure

Smart City

Smart Industry

Your benefits

- 4D technology® measures best in class high and low flows. (DN50: Start flow down to 0,005 m3/h and up to > 90 m3/h).

Immediate detection of leakages and network errors, suitable for fire flow. - Maximum installation flexibility.

Reliable measurements over the full flow range, independent of installation conditions. No straight runs needed even with 90 ° elbows, valves or pumps. - Accuracy by design: 4D technology® maximizes turndown ratio up to R1000.

Highest accuracy across the entire flow profile leads to a cutting edge dynamic range. - Homogeneous 4D-shape measuring pipe with dry sensors and no obstacles or cavities.

Minimal pressure loss enhances high flow capability and minimizes operating costs. Dry sensors lead to increased meter life-time, reliability and dirt resistance.

Applications

- Water measurement, e.g. drinking water or utility water (reservoirs, pumping stations, etc.)

- Suitable for difficult installation conditions such as placement directly before or after 90 ° elbows, valves or pumps

- The time-reverse acoustic principle enables a new level of measuring repeatability unaffected by flow perturbations, electromagnetic or grounding interference and water conductivity

Downloads

Links

Video 4D Technology 4-20mA Module Pulse Module Eco Module ModBus Module LoRaWAN Starter Kit (EN)Properties

- Minimal pressure loss <0.04 bar

- U0/D0, no need for flow conditioners

- Pressure ratings up to PN 16

- Bidirectional flow measurement

- Medium temperature up to 50 °C

- Degree of protection IP68

- Ambient temperatures from -20 °C up to 70 °C

- Tamper-proof

- Integrated medium temperature measurement

- Air detection

- External power supply

- Approved automatic detection of the direction of flow according to WELMEC 7.2 European Legal Metrology

Product information

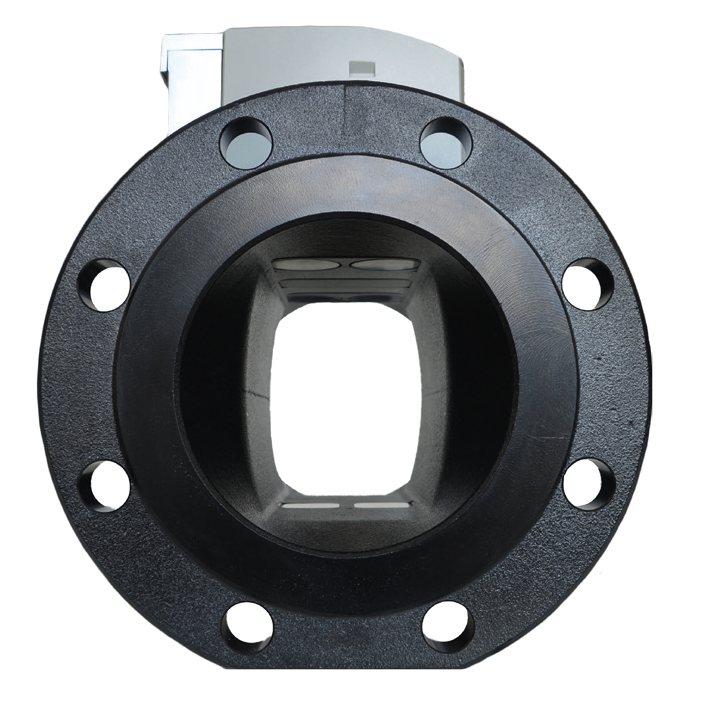

4D-shape measuring core

Due to the unique 4D-shape pipe design and the implemented 4D technology®, the measurement is independent of the flow profile. Dry sensors guarantee a highly accurate and reliable measurement performance over the entire meter lifetime.

The 4D-shape measuring core allows for installation of the meter directly behind a 90 ° bend or a valve. This flexibility results in minimal installation costs, since no additional on-site work has to be considered.

SONICO® EDGE – in Germany and Switzerland developed and produced. The patented time reverse acoustic principle enables a new level of measuring repeatability unaffected by flow perturbations, electromagnetic or grounding interference and water conductivity.

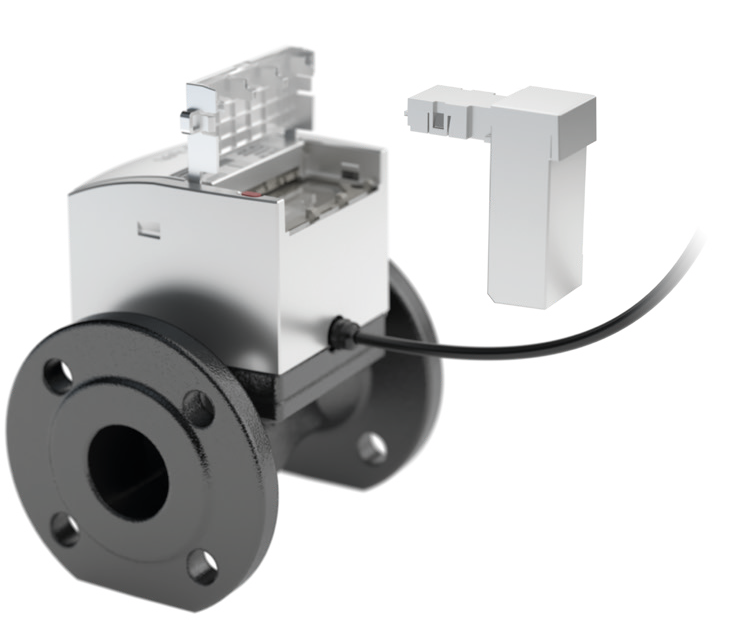

Ultimate communication

The 4D technology® platform supports a Near Field Communication (NFC) interface that ensure sustained connectivity during the entire product lifetime.

Maximum two of the following available communication module can be attached to the flexible NFC communication interface in parallel:

- Pulse: Pulse output (0.1 l; 1 l; 10 l; 100 l; 1000 l) configurable

- Current: 4-20 mA output configurable for uni- or bidirectional measurements.

- ECO E1 or E2: Low Power serial data interface (e.g. to connect a NB-IoT Modem)

- Modbus: Modbus RTU/ASCII protocol with extended flowmeter data

Technical data as acc. to MID/OIML certification

| Nominal flow rate | DN | mm | 50 | 80 | 100 | 150 | 200 | 250 | 300 |

|---|---|---|---|---|---|---|---|---|---|

| Dynamic | Q3 / Q1 | R | up to R1000 | up to R1000 | up to R1000 | up to R1000 | up to R1000 | up to R1000 | up to R1000 |

| Starting flow rate | Qstart | l/h | 25 | 50 | 80 | 200 | 300 | 450 | 600 |

| Starting flow rate | V'start | m/s | 0,0047 | 0,0042 | 0,0042 | 0,0045 | 0,0040 | 0,0060 | 0,0050 |

| Minimum flow rate ± 5 % | Q1 | m3/h | 0,04 | 0,10 | 0,16 | 0,40 | 0,63 | 0,63 | 1 |

| Minimum flow rate ± 5 % | V1 | m/s | 0,0076 | 0,0084 | 0,0083 | 0,0089 | 0,0084 | 0,0084 | 0,0084 |

| Transitional flow rate ± 2 % | Q2 | m3/h | 0,06 | 0,16 | 0,26 | 0,64 | 1,01 | 1,0 | 1,60 |

| Transitional flow rate ± 2 % | V2 | m/s | 0,012 | 0,013 | 0,013 | 0,014 | 0,013 | 0,013 | 0.013 |

| Nominal flow rate ± 2 % | Q3 | m3/h | 40 | 100 | 160 | 400 | 630 | 630 | 1000 |

| Nominal flow rate ± 2 % | V3 | m/s | 7,57 | 8,41 | 8,35 | 8,91 | 8,37 | 8,37 | 8,35 |

| Overload flow rate | Q4 | m3/h | 50 | 125 | 200 | 500 | 788 | 788 | 1250 |

| Overload flow rate | V4 | m/s | 9,47 | 10,51 | 10,44 | 11,14 | 10,46 | 10,46 | 10,44 |

| Maximal flow rate | Qmax | m3/h | 90 | 200 | 300 | 600 | 1100 | 1100 | 1500 |

| Maximal flow rate | Vmax | m/s | 17,04 | 16,82 | 15,66 | 13,37 | 14,61 | 14,61 | 12,53 |

| Nominal pressure | PN | bar | 16 | 16 | 16 | 16 | 16 | 16 | 16 |

Dynamic Range

| Installation direction | Temperature | DN 50 | DN 80 | DN 100 | DN 150 | DN 200 | DN 250 | DN 300 |

|---|---|---|---|---|---|---|---|---|

| Horizontal | T30 | R1000 | R1000 | R1000 | R1000 | R1000 | R1000 | R1000 |

| Vertical | T30 | R800 | R630 | R630 | R630 | R630 | R630 | R630 |

| Horizontal | T50 | R1000 | R1000 | R800 | R800 | R800 | R800 | R800 |

MID/OIML measuring accuracy

GWF 4D-Technology® offers a bidirectional turndown ratio R1000 as according to MID/OIML and is extremely robust against changes in the flow profile caused by bends, valves or pumps. The patented time-reverse acoustic principle enables a new level of measuring repeatability independent of flow conditions, electromagnetic or grounding interference and medium conductivity.

Industrial accuracy

In addition to MID/OIML calibration, GWF offers accredited industrial calibrations in accordance with ISO 17025 in the flow rate range from 0.005 m3/h to 600 m3/h.

Based on the GWF 4D-Technology®, an industrial calibration results in a measurement uncertainty of up to ±0.2% of the measured velocity ±0.5mm/s.

Typical pressure loss curve

The homogeneous 4D-shape measuring pipe ensures minimal pressure loss (< 0.04 bar on DN50 @ Q3), offering highest reliability at lowest operational costs.

Display Information

| 1. Volume unit indicator (digital) | 8. Main flow direction |

| 2. Non-billing relevant lines | 9. Battery level symbol |

| 3. Volume | 10. System alarm icon |

| 4. Tariff zone 1 | 11. Actual flow direction arrow |

| 5. Tariff zone 2 | 12. Flow rate |

| 6. Radio connection status | 13. Flow rate unit indicator (digital) |

| 7. Test mode information |

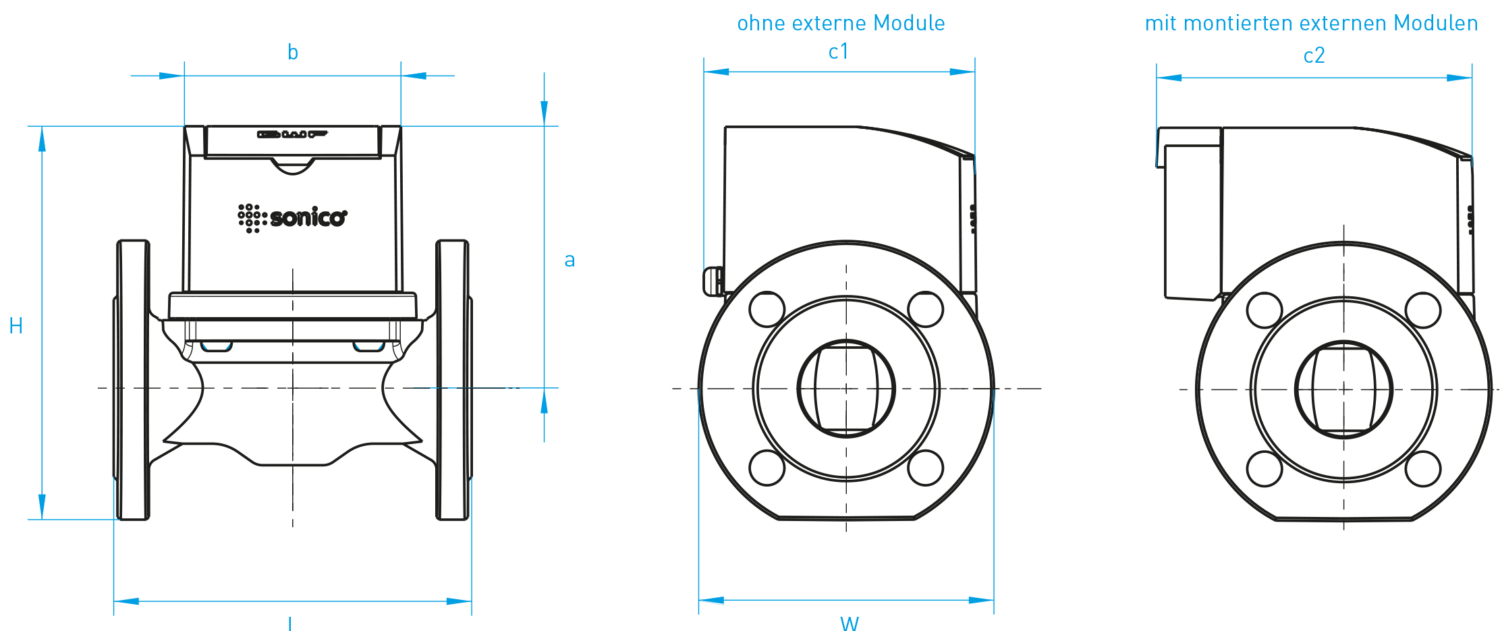

Dimensions and weight

| Nominal size (mm) | Nominal size (inch) | L (mm) | H (mm) | W (mm) | a (mm) | b (mm) | c1 (mm) | c2 (mm) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|

| 50 | 2 | 200 | 220 | 165 | 147 | 122 | 152 | 177 | 13 |

| 80 | 3 | 200 | 250 | 200 | 158 | 122 | 152 | 177 | 16 |

| 100 | 4 | 250 | 270 | 220 | 169 | 122 | 152 | 177 | 21 |

| 150 | 6 | 300 | 336 | 285 | 202 | 122 | 152 | 177 | 33 |

| 200 | 8 | 350 | 395 | 340 | 234 | 122 | 140 | 177 | 60 |

| 250 | 10 | 450 | 425 | 410 | 241 | 122 | 152 | 177 | 82 |

| 300 | 12 | 500 | 475 | 460 | 252 | 122 | 152 | 177 | 115 |

| Connection | Flanges: EN1092-1 PN 16, others upon request | ||||||||

Materials

Measuring channel:

- KTL- and powder-coated grey cast iron

Measuring adapter:

- KTL- and powder-coated grey cast iron

IP68 sealing:

- Screwed steel frame with glass and flat seal

Housing:

- ASA Luran plastic

Approvals

CE Design-examination Certificate in conformity with:

- 2014/32/EU (MID) (2019)

- OIML R49:2013 (2019)

- MCERTS Class 1

Drinking water approvals:

- KTW / W270 (2019)

- SVGW

- NSF-61

- WRAS

Power supply

SONICO® EDGE can be powered either mains (with suitable DC adapter) or by an external battery source1.

Mains power supply data:

- Input voltage: 24 V DC ± 10 %

- Max. charging current: 250 mA

- The integrated back-up battery (UPS2) ensures autonomous measurements for 24 h if external power supply is interrupted.

1) The external battery source to be provided by the customer. Examples may include eg solar power or wind turbine.

2) UPS – Uninterruptible Power Supply

External battery requirements:

- Input voltage: 5-15 V DC

- Nominal current: 30 mA (24 V)

- Max. peak current: 260 mA

- Battery life time: Depends on battery capacity